Quick tutorial #6: complete shock pistons guide for RC cars

Quick tutorials are a simple way to understand the settings of your car in a few minutes.

A subject, a short video, in order to answer 2 essential questions: WHY and HOW?

VIDEO

INTRO

Shock absorber pistons! A subject so vast and technical that we could spend several days on it!

Indeed, the suspension is one of the most important elements on your radio-controlled car. Reminder on my fluid mechanics lessons, gosh I'm feeling old already :-)

If your suspension is not adapted to track conditions, the behavior of your car will be really affected and it will be difficult for you to be fast or not to make mistakes.

Shock pistons are therefore the small plastic washers with holes that you find inside your shock absorbers.

I am regularly asked what oil I use in my shock absorbers, but it directly depends on the type of shock absorber pistons!

Before going into the details of the shock absorber pistons itself and its characteristics, let's do a little glossary.

In this tutorial, we will regularly talk about "pack", ie the locking effect of the piston.

This is THE key data that will change the behavior of your car on the track, and in my opinion several points will have an impact on the adjustment of the pack: the shape, the diameter and the holes of your shock absorber piston.

Depending on the settings you are going to use, your shock piston will more or less lock out (pack up) your suspension.

At first, imagine your shock absorber filled with silicone oil, and a solid piston, without any holes.

Your suspension will be completely blocked and you will have to force to activate your shock absorber. The pack up is huge.

Then imagine a single hole, the oil is going to have a hard time heading and going through your piston, the pack is very important.

Finally, imagine a piston with a lot of holes (always the same diameter as before). The oil will have no trouble getting through your piston, your shock will have very little pack.

We will come back to this later, because depending on the number of holes and their diameters, we will play on this pack to have a different behavior on the track.

Indeed, we will always seek to have an effective suspension in static on the table, but these adjustments can be different on track.

Then, your shock will oscillate between compression and rebound. Compression is the period during which the rod enters the shock body, and rebound the moment it exits the body.

Before any explanation, we will remain in a type of "standard" pistons.

To go further, some manufacturers indeed use double-acting or commonly called valve pistons, which we sell here.

These pistons will give a different compression to the rebound, so as to adapt the speed of compression or rebound according to the track conditions.

In my opinion, this kind of piston will perhaps give an advantage in certain conditions (slow and bumpy track), but the little extra that you will have in certain conditions, you will lose it 10 times in other conditions.

A simple shock piston already gives so many possibilities, I think it is essential to first understand the ease before venturing into the complex.

SHAPE, DIAMETER, THICKNESS, MATERIAL, HOLES...

These are indeed all the parameters that will greatly impact the behavior of your shock absorbers, and therefore of your car, on the track.

Not all pistons have the same diameter or the same shape, and this will impact your suspension.

We generally see flat pistons, and others with a tapered shape.

The flat side of the piston should be mounted up, the chamfered side down. You can watch our shock absorber mounting tutorial for more details.

A piston with a chamfer underneath will allow the oil to be directed more quickly towards the holes when rebounding, with a slight "valve" effect, very pleasant on tracks with holes, the wheel remaining more often in contact with the ground.

We will see it later in the thickness, but this famous chamfer will also have 2 advantages:

- the overall thickness of your piston will be smaller.

- the thickness in contact with the shock absorber body will be lower, and therefore your shock absorber will have less friction (your shock absorber will be more consistent).

Diameter

Most 1/8 off-road buggies on the market today have 16mm internal shock absorbers (12mm for a 1/10 off-road buggys).

In this case, some brands have pistons with an outside diameter of 15.8mm.

This is called the adjustment. The more your piston will be adjusted with the body (the diameter of the piston closest to the inside diameter of your shock), the more your shock will pack up (but still free to move inside obviously).

A tighter piston will therefore have less oil passing outside the piston, and the impact of the holes will be greater.

This is the main reason why many of you like pistons from another brand on your car, because these can be slightly smaller in diameter and provide more comfort.

Thickness

The thickness of your piston will also affect the behavior of your car.

A thicker piston will force the oil to spend more time passing through it.

Result: more pack, and therefore the feeling of a harder shock absorber.

A thinner piston will result in a more comfortable but less responsive car.

Material

The material used is generally Delrin.

We will always favor machined pistons, delivered directly finished.

The pistons delivered as standard on some cars on plastic clusters are to be avoided, because they are not machined but molded, and their tolerances are far from a machined piston.

Accuracy is therefore mediocre.

Some manufacturers also offer (brass) pistons, which are very heavy.

This added mass reduces the responsiveness of the shock, with basically the same effect as pistons with less pack.

So more comfort but less responsiveness/traction.

The holes

The most important element and what we talk about all the time! 6 holes, 8 holes, are you lost? We'll keep it simple!

Generally, we will always balance the number of holes with their diameter (and therefore the corresponding oil).

A piston with 8 holes will rather have holes with a diameter of 1.2mm or 1.3mm.

A 5-hole piston will be more with holes of 1.4 to 1.6mm.

When you go out of these values, you will go into different effects, and I do not advise you to do so.

The larger the holes surface (bigger holes or more holes), the weaker the pack.

The piston resists less in the shock absorber, your car will be more comfortable, will better absorb the holes and bumps of the track.

On the other hand, it will have quick mass transfers with a lot of chassis movement (squatting, dive under braking, roll in turns, etc.). Because of this, your car will be less precise and naturally slower on lap times.

On the opposite, the lower the holes surface (smaller holes or fewer holes), the greater the pack.

Your car will no longer bottom out. When landing from bumps, for example, your car will be less likely to hit the ground. It will also be more precise, more responsive, with more traction and faster.

It is therefore important to find the right compromise between comfort and speed, to test yourself to find your comfort zone!

TO GO A BIT FURTHER...

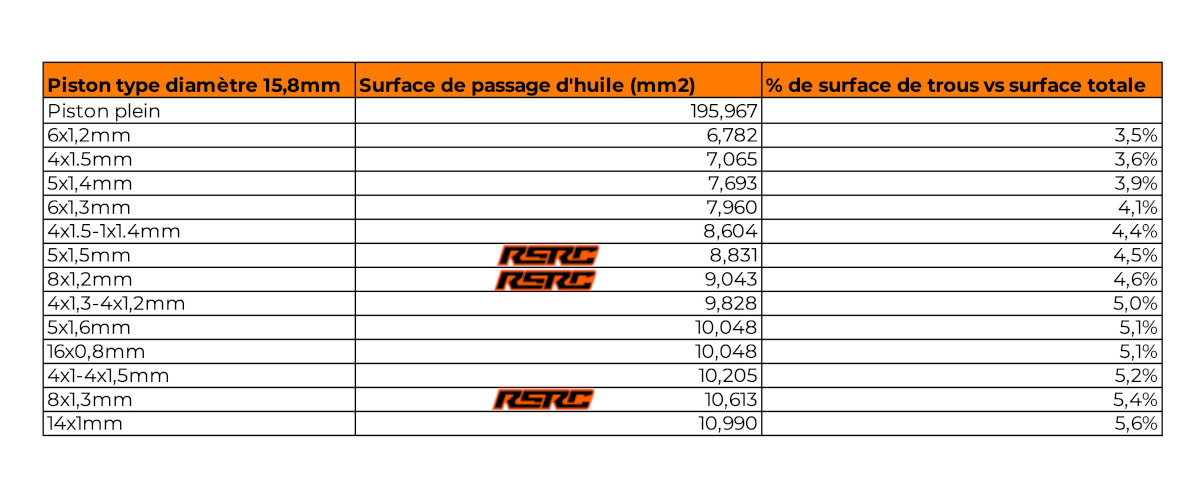

In order to better understand the effects of the piston and the holes, here is a quick calculation of surfaces, for a 16mm shock absorber, with a typical piston of 15.8mm:

In this example, the 6x1.2mm pistons have the least passing surface (6,782mm2 holes surface for a 3,5% surface versus the total piston surface), and therefore you will need a much softer oil to have a living suspension.

On the opposite, 8x1.3mm pistons will require the use of harder oil.

Last point. We see for example that the 5x1.6mm and 14x0.8mm pistons have the same percentage of passing surface.

So the same behavior on the track? Well no!

These pistons will not act in the same way at high speed (ie landing a jump) as at low speed (in turns).

Indeed, due to mechanical constraints, the oil, which is incompressible, will have more difficulty passing through a 0.8mm hole than through a 1.6mm hole.

For an equal passing thru surface, therefore, a piston with larger holes will have less difference in damping a fast or slow shock.

On difficult tracks, it will be better to use bigger holes for a more comfortable car.

The case of inclined SP (tapered) pistons: We have already discussed this point in a previous detailed tutorial.

TO SUMMARIZE

If I can give you good advice, it's to always keep things simple!

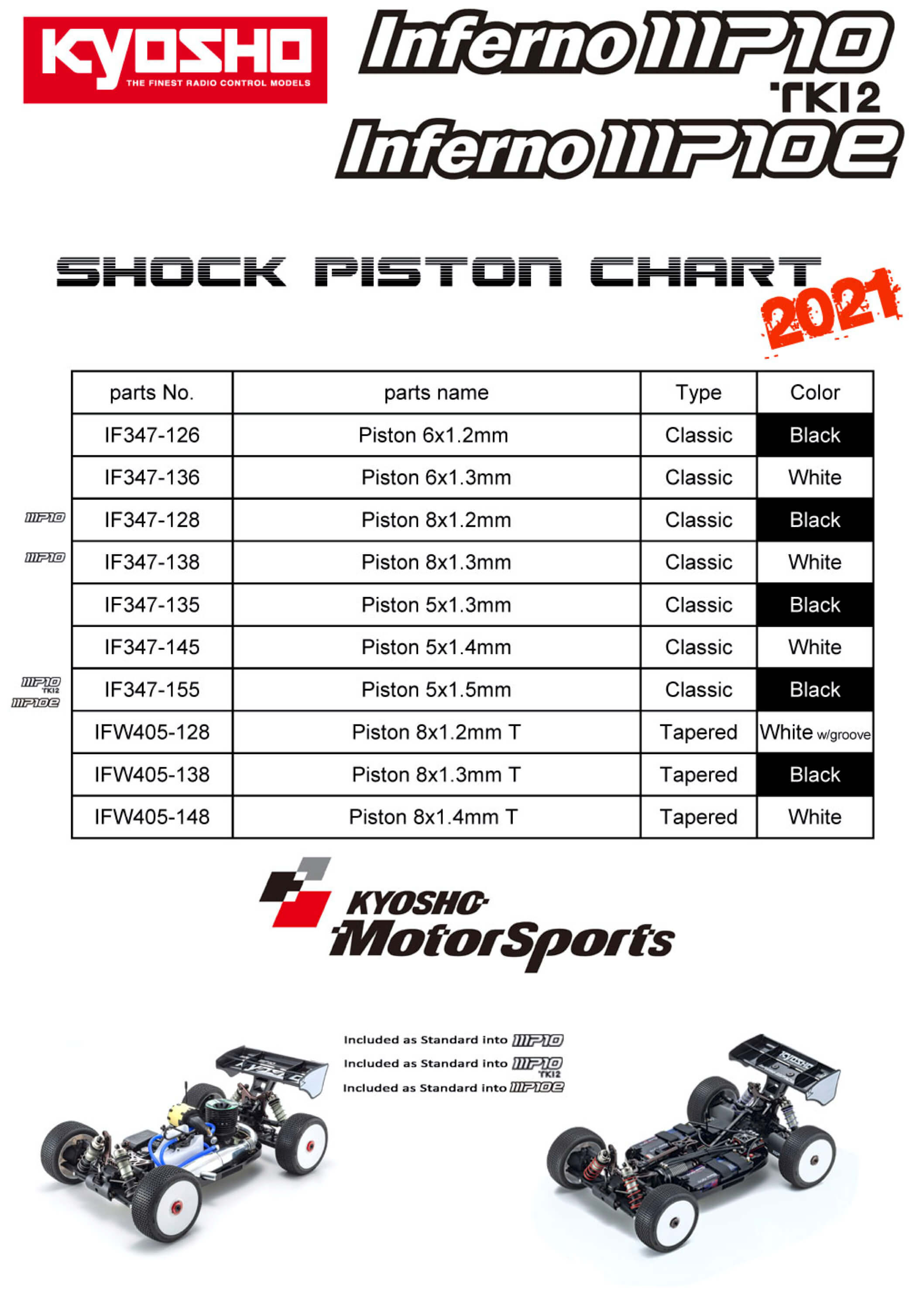

This is what I do on my Kyosho cars:

- On flat track, I use pistons with more holes, smaller, for more precision. Type 8x1.2mm (SP) or 6x1.3mm.

- On a bumpy track, I go with type 5-hole 1.5mm pistons.

Find our shock absorber pistons guide and references here!

Find our shock absorber pistons guide and references here!

See you soon for a new episode!

The Shark

Reno Savoya

Share this content

By RSRC 07/18/2022 14:43:48

Ennio: You can use 8 holes or 6 holes pistons

By Ennio 05/29/2022 17:29:01

Hi. Forse track flat but very slippery... What tipe pistone i cani start? Thanks

By Ludo 03/22/2022 07:31:58

Merci pour ce super tuto

By Jean J. 03/18/2022 22:40:14

Super tuto, merci pour toutes ces explications !

By RSRC 03/18/2022 22:35:36

Merci! Pour votre MP9, vous pouvez tout à fait partir sur ce que nous conseillons comme base de départ sur le MP10 TKI2 ou le réglage de Reno à la DNC 2022.

By Arthur 03/18/2022 19:10:39

Top le tuto ! Ça dégrossi bien ce qu'on peux essayer en fonction de l'état de la piste. Et le tableau des surfaces de passage d'huile va être très pour avoir toujours la bonne viscosité ! Par contre j'ai beau chercher je trouve pas de base de départ pour la viscosité sur un mp9 tki4 avec des pistons en 5x1.5. Aurais-tu une base à me conseiller ?